Categories:Комбіновані верстати

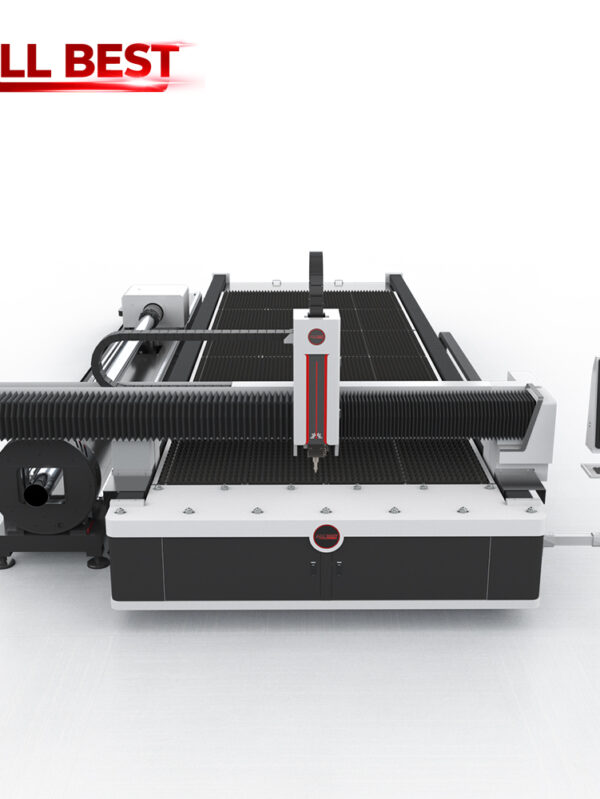

Лазерний верстат Bodor Laser C3T 6000 Вт

Доступність

В наявності

Потужність лазера: 3000 Вт, 6000 Вт

Комбінований лазерний верстат для різання листового металу та труб.

Додаткова інформація

| Потужність лазера | 3000Вт |

|---|---|

| Робоча зона | 3050*1530 мм, 4050*1530 мм, 4050*2030 мм, 6050*1530 мм, 6050*2530 мм |

| Виробник | Bodor |